In the Audi aeroacoustic wind tunnel a wind speed up to 300 km/h can be generated. Only when the airflow interacts accurately with the vehicle accurate measurements can be obtained.

In the Audi aeroacoustic wind tunnel a wind speed up to 300 km/h can be generated. Only when the airflow interacts accurately with the vehicle accurate measurements can be obtained.

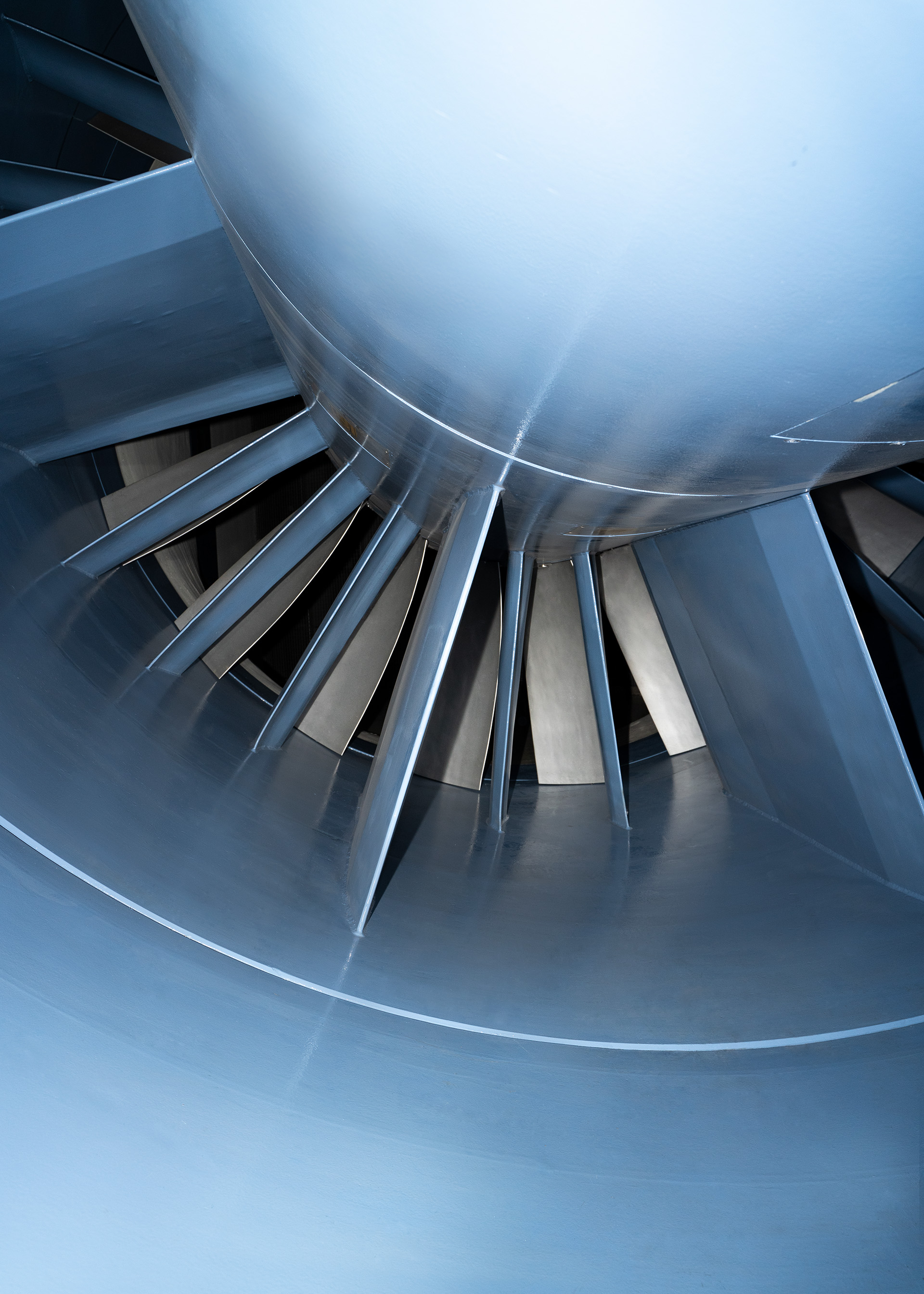

The first thing you notice when looking at the fan in the Audi aeroacoustic wind tunnel is the gap between each of the tips of the 20 blades on the wind tunnel rotor and the concrete shroud. A couple of perplexing centimeters. Is this an inefficient lack of precision? Dr. Moni Islam, Head of Development Aerodynamics & Aeroacoustics at Audi, provides reassurance: “When the fan runs at maximum power of 2.720 kW, the centrifugal force stretches the aluminum-coated blades, almost completely closing this gap.”

Then everyone has to leave the wind tunnel. After all, the forces that result in a wind speed of up to 300 km/h are generated in the test section. ”The 20 blades of the five-meter-wide fan slowly start to turn. The swirling airflow is first stabilized by the 27 guide vanes of the stator downstream of the fan. The air then turns two corners, where it is distributed evenly by specially designed turning vanes on its way to the test section. Grids downstream of the vanes break up the large-scale turbulence, which is unavoidable in the vicinity of the corners and the fan. The air then passes through a honeycomb layer to straighten the flow and into a large settling chamber downstream. It is then accelerated through the nozzle with a contraction ratio of 5.5 before reaching the Audi RS e-tron GT* at exactly the desired speed.

Specially designed turning vanes distribute the air evenly around the corners in the wind tunnel.

Thomas Redenbach is Head of Aerodynamics & Aeroacoustics Development – Vehicle Projects at Audi.

Specially designed turning vanes distribute the air evenly around the corners in the wind tunnel.

Thomas Redenbach is Head of Aerodynamics & Aeroacoustics Development – Vehicle Projects at Audi.

The vehicle stands on a precision balance which measures the aerodynamic forces on the vehicle. Its wheels stand on four small belts. A wide belt under the car simulates the movement of the road relative to the vehicle at all running speeds. In addition, high-precision adjustable perforated plates in the floor in front of the vehicle extract part of the airflow—the so-called boundary layer—before it reaches the car. Aerodynamicists call this design “full ground simulation”: This guarantees realistic airflow around the vehicle. And if you think it sounds complicated, that’s because it truly is.

Dr. Kentaro Zens, the aerodynamicist responsible for the Audi RS e-tron GT*, standing next to the aerodynamically optimized underbody of the sports car.

Dr. Kentaro Zens and Thomas Redenbach discuss the measurement readings. Behind the window, the Audi RS e-tron GT* stands in what is known as the plenum of the wind tunnel.

Dr. Kentaro Zens, the aerodynamicist responsible for the Audi RS e-tron GT*, standing next to the aerodynamically optimized underbody of the sports car.

Dr. Kentaro Zens and Thomas Redenbach discuss the measurement readings. Behind the window, the Audi RS e-tron GT* stands in what is known as the plenum of the wind tunnel.

Going to great lengths to achieve the perfect airflow

Dr. Kentaro Zens, the development engineer responsible for the aerodynamics and aeroacoustics of the Audi RS e-tron GT*, says: “On the road, the vehicle moves through the air. Here in the wind tunnel, it’s the exact opposite: The vehicle is stationary and we channel the air around it as evenly as possible. We go to great lengths. Only when the airflow interacts accurately with the vehicle are we able to obtain accurate measurement results that we can rely on.”

Zens sits at his workstation next to the control panels with which the operators regulate the wind tunnel. He can read all the relevant data on screens: What is the drag coefficient, how high is the front-axle lift, how high is the rear-axle lift, at what wind speed and what belt speed?

Standing next to him is Thomas Redenbach, Head of Aerodynamics & Aeroacoustics Development – Vehicle Projects: “When the Wind-Tunnel Center went into operation, it was the first automotive wind tunnel worldwide to combine ground simulation of real-world road conditions for aerodynamics with such extremely quiet aeroacoustic functionality.”

Today, the wind tunnel runs up to six days a week from 7:00 a.m. to 10:30 p.m. in two shifts. And when the Worldwide Harmonized Light-Duty Vehicles Test Procedure (WLTP) certification was introduced by legislators, its capacity was utilized to the full. Moni Islam says: “The complexity of this wind tunnel called for the full commitment and technical expertise of our sister department, which has been operating it for us every day for many years. At the time, our colleagues from wind-tunnel operations provided us developers with 23 hours of testing time per day, as we are required to submit certified wind-tunnel data to legislators as proof of the WLTP values.”

“Every count by which we can improve the drag coefficient increases the vehicle’s driving range.”

Dr. Moni Islam

Dr. Moni Islam is Head of Development Aerodynamics & Aeroacoustics at Audi. Here, he explains how the active noise-cancelling system of the wind tunnel works.

Dr. Moni Islam is Head of Development Aerodynamics & Aeroacoustics at Audi. Here, he explains how the active noise-cancelling system of the wind tunnel works.

The smoke shows how the airflow behaves after passing the exterior mirror of the Audi RS e-tron GT*.

The aerodynamicists can access the most important vehicle and wind-tunnel data at their workstation at all times.

The smoke shows how the airflow behaves after passing the exterior mirror of the Audi RS e-tron GT*.

The aerodynamicists can access the most important vehicle and wind-tunnel data at their workstation at all times.

Simulation cannot replace the wind tunnel

Nevertheless, computer simulations are also playing an increasingly important role in aerodynamic development. Computational Fluid Dynamics (CFD) simulation reproduces airflow on the computer to enable analysis and visualization of flow patterns. So why the time-consuming and expensive work in the wind tunnel? Thomas Redenbach: “The wind tunnel is our everyday tool and also enables us to validate the results from the simulation. We want to keep developing the simulations and, in order to ensure they are valid and accurate, we have to check the calculations against the test results.”

Yet computer simulations are getting better and better and becoming more and more important. Kentaro Zens says: “With the Audi RS e-tron GT*, we did an exceptionally large amount of simulation work—over nine million CPU-hours. I spent 150 hours in the wind tunnel with the vehicle, which isn’t very much at all. By way of comparison, it was 600 hours for the Audi R8.” This indicates not only the quality of the Audi RS e-tron GT* design but also that the development process was significantly shorter—a path Audi is aiming to take also with future models.

Moni Islam adds: “The wind tunnel and CFD are two complementary tools for the aerodynamicist. The wind tunnel is very accurate and quick, enabling us to work highly efficiently in the dynamic development process. Simulation provides us with an incredible amount of information but requires effort in terms of preparation of the models and analysis of the results. With only one of these two tools, state-of-the-art aerodynamic development would not be possible.”

“We invest an enormous amount of time in the last 20 percent of the aerodynamics optimisation.”

Thomas Redenbach

Leveraging potential in terms of range

For electric vehicles like the Audi RS e-tron GT*, the full package offers benefits in terms of aerodynamics (the closed underbody being just one example of where this applies). However the challenges facing the 31-strong aerodynamic vehicle development staff in Moni Islam’s department are growing. He defines their aim as follows: “Every count by which we can improve the drag coefficient increases the driving range.”

Aerodynamicists identify this potential in the vehicle through simulation results that indicate sensitivities: If I change the geometry slightly at point X of the shape, how much does that affect the airflow? And then begins what Islam describes thus: “Aerodynamics is also meticulous detective work because you can’t see the air. You have to try to narrow down the problem using an analytical approach based on the values delivered by the balance in the wind tunnel.”

To achieve this, the engineers also work with various add-on parts generated with rapid-prototyping technology. Initially, CAD designs are created to define the geometries of the components—for example, an air intake on the front apron. The colleagues from model management then convert the desired variants, of which there may be several, into a test component using this advanced technology. The different variants of the components are subsequently tested in sequence on the vehicle model. The measurements provide drag and lift coefficients. These results are then selectively compared with the CFD simulations of exactly the same configuration to ensure valid simulation results.

The vehicle can be raised over the balance to enable analyses and modifications during work in the wind tunnel.

Unremarkable, but effective: A plastic lip on the underbody directs the airflow highly efficiently.

The vehicle can be raised over the balance to enable analyses and modifications during work in the wind tunnel.

Unremarkable, but effective: A plastic lip on the underbody directs the airflow highly efficiently.

Detective work for every drag count

“You can develop 80 percent of a vehicle’s aerodynamics in 20 percent of the time. But we invest an enormous amount of time in the last 20 percent of the aerodynamics—teasing out the drag counts in a host of tiny optimisation steps,” says Thomas Redenbach, describing the detective work in the wind tunnel. “It takes this high level of dedication and attention to detail to produce top-quality results.”

So what was the most difficult detail in terms of airflow in this Gran Turismo for the aerodynamics experts responsible for the Audi RS e-tron GT*? Kentaro Zens thinks for a while. “The front apron with its four interconnected ducting components. The air flows into the intakes, the shutter inside closes—and that’s when the problem starts. The air can escape all over the place and you don’t want that. Keeping the airflow under control here and fine-tuning it precisely is critical. It’s a huge team effort as the colleagues from vehicle safety, parts engineering, production and assembly all have to work with me.”

Zens also makes specific reference to the design of the so-called air curtains in interaction with the wheel arch: “We had close coordination with the Audi designers on a weekly basis. This resulted in an optimal aerodynamic transition from the front end to the side around the air curtain that also fits seamlessly into the overall design as a coherent theme. Everything about the Audi RS e-tron GT* has a function and a purpose. That’s authentic functionality, which is something I really like about the vehicle.”

A smoke lance can be used to make the airflow visible. Here, it shows the optimum path of the flow through the air curtain to the wheel arch.

A smoke lance can be used to make the airflow visible. Here, it shows the optimum path of the flow through the air curtain to the wheel arch.

“The aim of aerodynamics is to facilitate design.”

Dr. Kentaro Zens

Another example is also close to his heart: the sharp edge integrated into the taillight. “There are complex vortices at the rear of the Audi RS e-tron GT*, in particular due to its pronounced three-dimensional shape. Guiding the airflow cleanly around this is a challenge. In the simulation, we saw that there was still room for improvement around the taillight.”

Fortunately, César Muntada, Head of Light Design at Audi, was also present in the wind tunnel during this test session. He quickly modeled a slight outward curve into an indentation in the taillight on the clay model, which now appears in exactly the same form on the production vehicle. This modification enabled designers and aerodynamicists to ensure that the airflow separates at the rear in a controlled manner instead of turning inward and generating new vortices (which would significantly impact the drag coefficient). “In aerodynamics, we aim to facilitate design,” says Kentaro Zens, describing this collaboration. And that includes meticulous detective work in the wind tunnel.

The rear spoiler of the Audi RS e-tron GT* can assume three different positions to ensure effective airflow control under all driving conditions.

The fan of the wind tunnel has a power consumption of up to 2,720 kW.

The rear spoiler of the Audi RS e-tron GT* can assume three different positions to ensure effective airflow control under all driving conditions.

The fan of the wind tunnel has a power consumption of up to 2,720 kW.